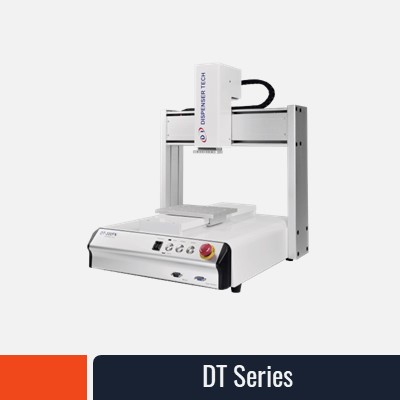

Products Details

The in-line automation facility can be applied to various processes in industrial sites that require dispensing, such as under-fill, UV bonding, and epoxy molding. The system can transfer, align, apply a dispensing position, and dispense products with the all-in-one facility.

Specification

| Dimension | 1200 x 1150 x 1680 (㎜) |

| System Configuration | CONVEYOR + 3-AXIS CARTESIAN ROBOT + DISPENSER |

| Power | AC220V, 50/60Hz 50A |

| Control Method | PLC, TOUCH, TOUCH CONTROLLER |

| User Interface | OPERATION PC, TEACHING PENDANT |

| Power Consumption | 5 bar over |

| Operating Air Pressure | 0.4~0.8 MPa |

| Dispensing Robot | 3-Axis Cartesian Robot (X:300, Y:200, Z:200㎜) |

| Robot Speed | LM GUIDE (MAX 600㎜/sec) |

No resources for this product.