What is a progressive cavity pump and what is it used for?

What is Progressive Cavity Pump?

Progressive cavity pumps are a form of rotary positive displacement pump. They are additionally referred to as PC pumps, progressive cavity pumps, eccentric screw pumps, and mono pumps. These pumps are made specifically for moving various kinds of fluids, from thick sludges with viscosities up to one million cst to liquids with extremely low viscosity levels Progressive cavity pumps are renowned for their capacity to handle gassing or multiphase liquids with gas slugs, which are common during the extraction of crude oil, in addition to viscous and solid-laden fluids.

As the pump's volume of output and speed are precisely proportional, the pumping rate is very consistent and linear at different pressures. With capabilities of up to 600 m³/h and pressures of up to 48 bar, progressive cavity pumps deliver one of the largest flow and pressure combinations possible from positive displacement pumps. These pumps have efficiencies between 55% and 75%, which makes them suitable for fluids with viscosities higher than 5 CST. This makes them suitable for a wide range of industrial uses.

How does a Progressive Cavity Pump work?

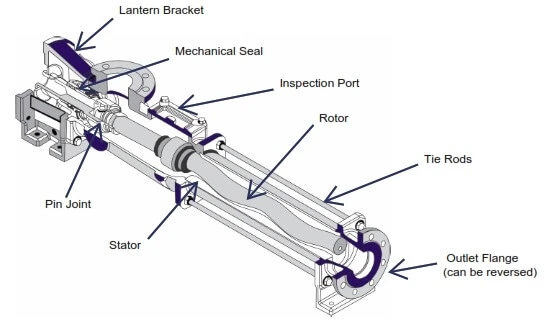

A progressive cavity pump has a motor combined to a gearbox, allowing it to operate at lower RPMs than centrifugal pumps with the same horsepower. The gearbox powers a rotor, which rotates inside a stator. The rotor is usually metallic in nature, while the stator is made of a rubbery material. The rotor moves inside the stator, producing a sequence of chambers that allow the fluid to flow slowly and continuously through the pump.

Each rotor cavity generates pressure, and systems with high pressure frequently use a lot of rotors and stators. Each rotor may produce pressures of up to 6 bar, and pressures can reach 48 bar when multiple rotors are used. Due to the small gap between the rotor and stator, the fluid being pushed must act as lubricant. Any variations in temperature can cause the stator to expand, possibly causing slicing or damage when it comes into contact with the rotor. Progressive cavity pumps are excellent for transferring viscous, lubricating fluids that may contain particles. However, corrosive fluids might limit the stator's life, making the peristaltic pump a better option for particular applications.

Parts of Progressive Cavity Pump

- Rotor: The main rotating part of a machine is usually composed of hardened metals, tool steel, stainless steel, or cast iron. The fluid passes through the pump by the cavities created by the rotor's distinctive circular shape.

- Stator: The pump is not suitable for liquids based on solvents since the stator is made up of elastomer substances, such as NBR or FKM, instead of PTFE. It is possible to create stator sides with equal or dissimilar thickness. Equal-walled stators are devices that use less energy and produce less torque and vibration.

- Universal Pin Joint: This allows the rotor to spin irregularly within the stator by joining it to the drive shaft.

- Gearbox: Allows the pump to operate at the lowest possible RPMs necessary. Discover how our advanced progressive cavity pumps integrate these components for optimal performance."

Progressive Cavity Pump Applications

Progressive cavity pumps from Dispense Robotics are utilised in numerous different sectors because of their flexibility and flexibility. The following are a few of the main applications:

- Wastewater Treatment: These pumps are crucial in water treatment facilities since they are used for polymer dosage and the transfer of thicker and processed waste.

- Oil & Gas: Progressive cavity pumps are frequently used for cutting, separation supply, multiphase, drilling mud and crude oil extraction transfers. They are also perfect for fluid injection in isolated oil fields.

- Biogas: To ensure smooth operation in biogas producing facilities, they are frequently used to move biomass and digested matter.

- Pulp and Paper: Recycled paper, pulp, fillers, and dyes are all moved through the use of these pumps in paper mills.

- Edible Oils: For operations such as oil extraction, oil extraction, filter press feed, and oil separator feed, progressive cavity pumps are suitable.

- Wine Production: Progressive cavity pumps are an essential tool used by vintners for grapes pressing, wine filtering, and moving must and the waste.

Dispense Robotics Progressive Cavity Pumps Benefits

- Low Pulsating Flow: These pumps have a smooth, little pulsing flow because of their rotating motion at low RPMs. Further decreasing flow pulsation are the long-pitch rotor and the stator's even wall construction.

- Low Shear Handling: Resins, sticky foods, and fluids like oil and water mixtures are examples of fluids that progressive cavity pumps excel at handling. Their ability to handle these fluids without changing their consistency is a crucial benefit for sectors like the oil and gas industry.

- Reversible Operation: By using these pumps in reverse, obstructions can be removed and hoses drained. They are suitable for tanker loading and unloading operations because of this capability.

- Broad Range of Fluid Handling Capabilities: Abrasive materials, gas slugs, big solids, viscous liquids, and fibrous solids are just a few of the fluid types that progressive cavity pumps can handle. They are the best at handling viscosities ranging from 1 cst to 1 million cst.

- Self-Priming: The pump can self-prime up to eight meters due to its powerful suction abilities, which are made feasible by precise tolerances in its construction.

- High Accuracy: The pump is ideal for accurate measuring and dosing applications since its flow rate is exactly related to its speed.

- High Flow and Pressure: One of the most powerful positive displacement pumps on the market, progressive cavity pumps may deliver flow rates of up to 600 m³/h and pressures of up to 48 bar. It is well known that these pumps can handle viscous mud without choking due to their non-clog design. They include large inspection apertures that allow for simple inside inspection without having to separate from the pipework in the event that clogging does occur.

Model Variants

Dispense Robotics offers a range of progressive cavity pump designs to cater to different industrial needs:

Hopper Pumps

These pumps come with hoppers that handle materials with high dry content, such as viscous liquids and large solids. Auger screws or paddles are often used to aid material flow into the

pump.

Food-Grade Pumps

Designed for hygienic applications, these models comply with 3A and EHEDG standards for easy cleaning. They can be mounted on trolleys for mobility.

Macerator Pumps

Featuring inline grinders to break down solids before they enter the pump, these models are ideal for industries that deal with solid-laden fluids.

Vertical Immersion Pumps

These pumps are designed to be submerged in fluids, eliminating NPSH issues. They are suitable for open or closed drain applications.

Multiphase Pumps

Capable of handling viscous oil, gas slugs, sand, and water, these pumps are perfect for multiphase boosting applications.

Wobble Pumps

These smaller pumps feature a single joint design, which causes the rotor to wobble instead of rotating in a full circle, making them ideal for certain niche applications.

Pump curve

Pump curves are different from centrifugal curves in that they are linear, demonstrating the unit's capacity to handle liquids with a range of viscosities with minimal effect on pump performance. Moreover, speed acts as the bottom axis instead of flow, since flow is proportional to speed. Unit speed can operate as low as 50 rpm, which is significantly lower than centrifugal.

FAQs About Progressive Cavity Pumps

What is the Progressive Cavity Pump ISO Standard?

For progressive cavity pumps, the International Organisation for Standardisation (ISO) has an international standard called ISO 15136-1:2009. The design, manufacturing, handling, and efficiency ratings of progressive cavity pumps used in the natural gas and petroleum sectors are all covered by this standard. Further specifications include ANSI 3.1-3.5 for rotary positive displacement pumps and API 676 for petroleum applications.

Can Progressive Cavity Pumps run dry?

No, progressive cavity pumps shouldn't ever run dry. Without fluid, the rotor and stator are not moisturised, causing rapid and permanent harm to the pump. The mechanical seal also requires cooling; without fluid, it can overheat and shatter. Sensors or float switches can be placed to prevent dry running by automatically shutting off the pump when fluid levels drop.

What Viscosity Can These Pumps Handle?

Progressive cavity pumps can handle viscosities as high as 1 million cst, making them suitable for highly viscous fluids, sludges, and slurries.

What Types of Solids Can Progressive Cavity Pumps Handle?

These pumps can manage fluids with up to 50% dry matter content and solids up to 30mm in size. Special designs can accommodate higher solid content when combined with slurry via a liquid injection port.

Does My Progressive Cavity Pump Require a Bypass Valve?

It is advised to have a bypass valve in order to safeguard the pump against overpressure. When pressures increase, an integrated bypass circulates the fluid to offer temporary protection. The more over time fix, however, is an external bypass that returns the fluid to the source.

What Distinctions Exist Between a Centrifugal and Progressive Cavity Pumps?

Centrifugal pumps use a propeller to create flow, whereas progressive cavity pumps use a helical rotor and stator. Centrifugal pumps work better in high-flow, low-viscosity applications, while progressive cavity pumps are better suited for high-viscosity fluids and accurate metering.

What Are the Common Failures of Progressive Cavity Pumps?

Common issues include temperature sensitivity, where the elastomer stator can swell or deteriorate, and vibration problems, which can lead to shaft seal failures. Ensuring proper lubrication and choosing the correct pump for the application can minimize these issues.

Upgrade your fluid handling with Dispense Robotics' reliable and efficient progressive cavity pumps. Built for high performance across a range of industries, our pumps handle viscosities up to 1 million cst with ease. Improve your operations today contact Dispense Robotics to get your progressive cavity pump solution!