Thermal Interface Materials Dispensing (TIM)

Are you struggling with thermal management for your electronic devices? Look no further because Thermal Interface Materials Dispensing is the key to all your heat dissipation efforts. If you have ever wondered how to transfer heat from one part to another effectively, Thermal Interface Materials (TIM) are the answer. This article takes a closer look at what TIM dispensing is, TIM types, properties, and the processes involved in TIM dispensing. Additionally, we will discuss the challenges and solutions in TIM dispensing.

Let's get started.

What is Thermal Interface Materials Dispensing (TIM)?

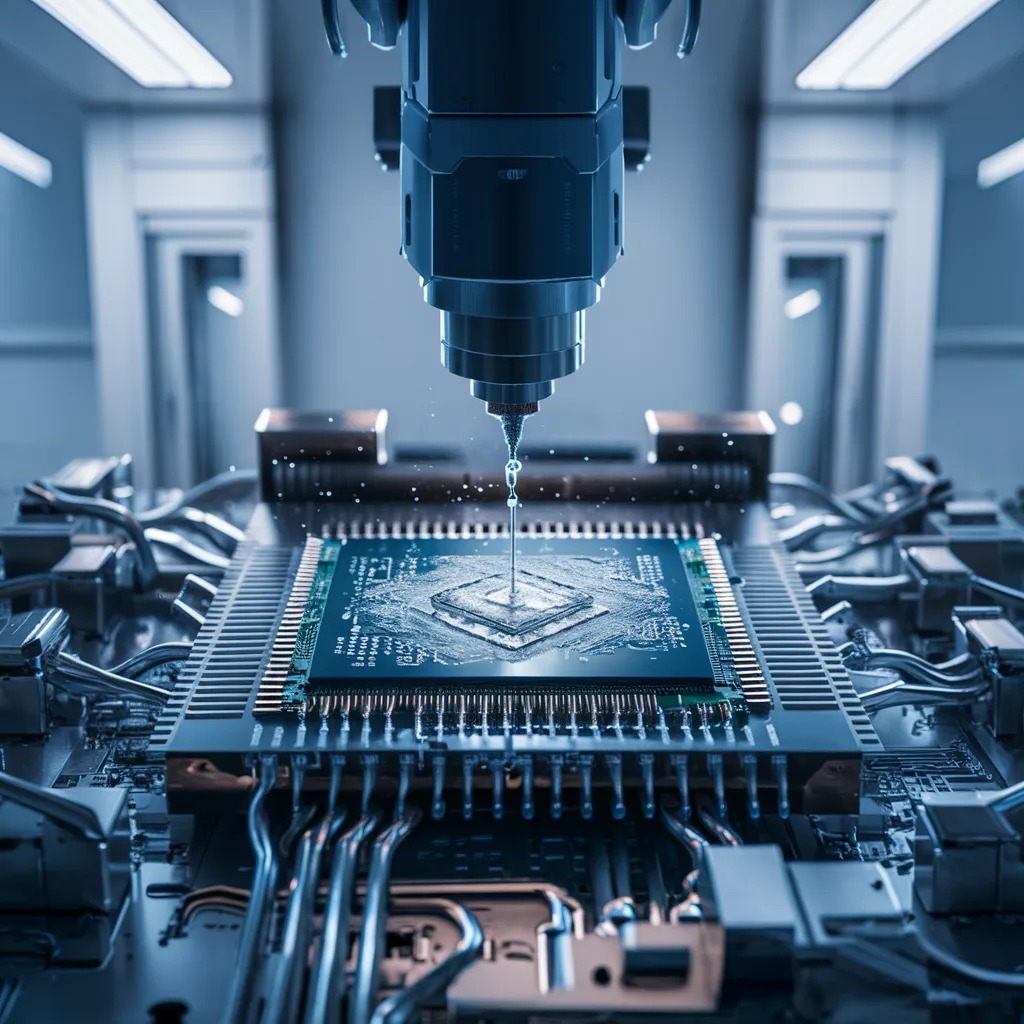

Thermal Interface Materials Dispensing (TIM) is a highly precise process critical for effective heat management in electronic devices. This high-precision dispensing involves materials designed to promote heat transfer between components such as microprocessors, heatsinks, and other electronic parts. TIM dispensing involves the precise application of thermal interface materials, such as thermal greases, pads, adhesives, or phase change materials, to establish a low-resistance thermal pathway between components. This results in optimal heat transfer, allowing electronic devices to function reliably and perform effectively over time.

Where is TIM Used?

Thermal interface materials (TIMs) are used in various applications to enhance heat transfer.

- TIM 1: Applied between a flip-chip integrated circuit (IC) and a heat-spreading lid.

- TIM 2: Used between a finished package, component, or module and a heat spreader, such as a case, metal housing, or heatsink.

- TIM 1.5: Placed between an IC without a lid and a heatsink.

Thermal Interface Material Dispensing Equipment

Types and Properties of TIM

There are various types of Thermal Interface Materials for different applications and requirements. Here are some common types and their basic properties: Here are some common types and basic properties:

1. Thermal Greases:

Thermal greases are highly viscous compounds usually containing silicone or non-silicone-based materials combined with thermally conductive fillers such as metal oxides or ceramics. These greases conform well to fill micrometric gaps on surfaces, improving thermal contact resistance.

2. Thermal Pads:

Thermal pads are pre-formed pads fabricated using elastomeric materials filled with thermally conductive fillers. They are easy to handle during assembly operations due to their consistent thickness. Thermal pads exhibit good thermal conductivity and provide electrical insulation, making them suitable for electronic components.

3. Thermal Adhesives:

Thermal adhesives serve dual functions: heat transfer and mechanical bonding between components. These materials, including epoxies, acrylics, and silicones, offer high thermal conductivity and strong adhesion properties, combining reliable thermal performance with mechanical stability.

4. Phase Change Materials (PCMs):

PCMs undergo a phase transition, typically from solid to liquid, with rising temperatures. During this transition, they absorb and store thermal energy, reducing sharp temperature rises. PCMs exhibit excellent thermal conductance in their molten state and solidify when they cool, making them ideal for transient heat management applications.

Understanding the characteristics of each type of TIM helps engineers make informed decisions to optimize thermal performance and ensure device longevity Now let's discuss the process of TIM dispensing.

The Process of TIM Dispensing

The process of TIM dispensing involves several steps to achieve reliable and uniform coverage between mating surfaces. Here’s an overview:

1. TIM Selection: The selection of the appropriate type of TIM should be based on application needs, including thermal conductivity, viscosity, curing time, and compatibility with substrate materials.

2. Dispensing Equipment Setup: Dispensing of TIM can be performed using a number of precision dispensing equipment, including manual syringes, pneumatic dispensers, or automated dispensing systems. This is set based on the required viscosity and dispensing volume to place a precise application like volumetric dispensing systems.

3. Dispensing Technique: TIM is dispensed onto one of the mating surfaces in a controlled manner. The dispensing technique varies depending on the type of TIM and the desired coverage area. For example, a continuous bead, dot matrix, or screen printing technique may be employed.

4. Mating Surfaces Assembly: Surfaces for mating should be properly aligned and joined tightly, not only after the application of TIM but also for proper contact with it and distribution.

5. Excess Material Removal: Any TIM that bleeds off because of the assembly process will be removed so as not to contaminate and spoil the finish. This can vary from utilizing a spatula, wiping cloth, or even automated cleaning depending on application requirements.

6. Curing or Thermal Cycling: Some TIMs need to be cured to ensure proper functioning. Thermal cycling can also be performed to allow better flow and wetting of the TIM, which helps to improve the contacting mating surface area.

So, these steps enable the engineers to effectively apply TIMs so as to increase the conductance of enhanced thermal power and avoid heat-related issues up to a certain level that ensures a service life and reliability for electronic devices.

Applications of TIM in Various Industries

Thermal Interface Materials have applications in numerous industries:

1. Electronics: TIMs help to dissipate heat in electronics, such as computers and smartphones so that the device does not overheat and consequently increases the lifetime of such devices.

2. Automotive: Required for thermal management in engine control units, LED lighting, and EV battery packets so that stable operation is possible under severe working conditions.

3. Telecommunication: Used in routers and base stations, TIMs maintain equipment temperature for reliable communication.

4. Medical Devices: TIMs ensure accurate performance in diagnostic and imaging equipment by managing heat in critical components.

5. Aerospace and Defense: TIMs in such applications dissipate heat within avionic and radar systems to ensure equipment reliability in harsh environments.

6. Consumer Appliances: TIMs prevent overheating in household appliances like refrigerators and air conditioners, improving energy efficiency.

TIM dispensing could be challenging but mastering the following approach will help you:

Viscosity Variations:

The general variation of the viscosity within the TIMs ranges from very thick paste to thin fluids.

However, these variations can be effectively taken care of by changing some parameters of the automated fluid dispensing equipment and selecting an appropriate nozzle for viscous material dispensing.

Surface Compatibility Concerns:

Different surfaces demand tailored TIM formulations. Prioritize compatibility testing and consult material data sheets to select the best TIM for each substrate, ensuring optimal adhesion and thermal conductivity.

Precision Dispensing:

Achieving uniform coverage while avoiding air entrapment or excess material requires finesse. Invest in precision dispensing equipment, calibrate regularly, and fine-tune parameters like pressure and speed to achieve consistent results.

Curing Constraints:

Some TIMs need to be cured following dispensing, an operation that can produce time delays, and the process has to continue at the scheduled starting time.

Plan assembly sequences in advance so that bottlenecks are minimized, or else look for alternative TIM designs that cure at high speed.

Automation Advantages:

While manual dispensing offers flexibility, automated dispensing robots can enhance consistency and throughput. Evaluate the cost-benefit of investing in dispensing automation solutions, considering factors like production volume and complexity.

Running through these challenges upfront helps you streamline TIM dispensing processes, optimize the management of heat in electronic devices, and create an effective design suited best for high performance and long life.

Conclusion

In conclusion, it appears that Thermal Interface Materials Dispensing is a promising way to get out of problems related to thermal management in electronic devices. Through knowledge about the types, properties, and processes involved, an engineer would be able to optimize heat conductance and enhance the reliability of the device.

The above given proactive strategies will help you overcome hurdles due to the issues of the TIM dispensing.